Cal Nano Services

Cryogenic Milling & Grinding

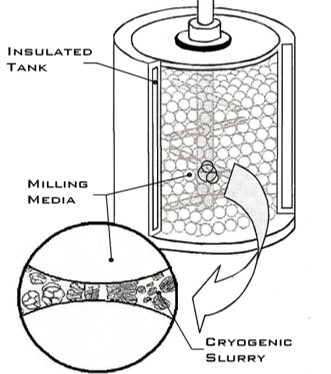

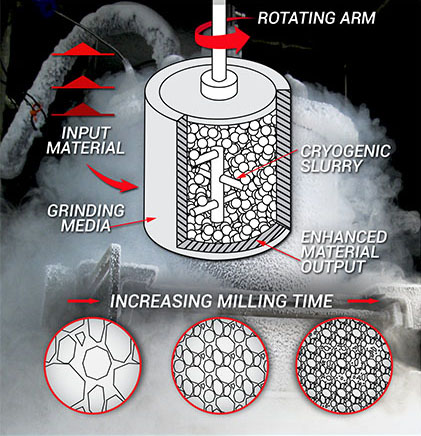

Cryogenic milling gives you the ability to produce nanostructured and nanocrystalline materials with superior mechanical properties, outperforming conventional alternatives. This process also enables precise particle size reduction and allows you to create custom alloys from elemental materials, unlocking new possibilities for advanced applications.

With state-of-the-art cryomilling systems, you can safely and efficiently process elemental metals, metal matrix composites, intermetallic compounds, and more, achieving the exact material characteristics you need.

Whether you're developing new materials, refining existing ones, or engineering custom alloys, California Nanotechnologies provides the expertise and technology to help you succeed. Take your materials to the next level—contact us today!

Cal Nano Cryomilling Toll Services:

- Collaborative R&D to High-volume production services are available

- High-quality customer service & quick turnaround times

- Customers can provide powder or it can be sourced by Cal Nano

- Improving material strength through grain refinement in metallics

- Creating custom metallic alloys & refractory alloys

- Particle size reduction for ceramics, metals and polymers with the ability to reduce to sub-micron in certain materials

- Homogeneously mixing materials faster and more effective than traditional methods

- During cryomilling the material is fully submerged in liquid nitrogen or liquid argon, making it ideal for moisture sensitive or materials prone to smearing.

- Inert atmosphere suited for processing hazardous materials containing volatile components.

CRYOMILL BATCH SIZES

R&D – 500 grams and 1 kilogram

Pilot-Scale – ~7-50 kilograms

Production Scale - 100-10,000s of kg processing

TYPICAL MATERIALS

Metallics – Magnesium, Aluminum, Titanium, Iron, Nickel, and their alloys

MMC’s – Metal with Al2O3, B4C, YSZ, and more

Battery materials - Nd, FeN, etc.

Refractory materials - Tungsten, Niobium, Zirconium, Hafnium, Tantalum, and more

Polymers (particle size reduction)

Some applications for powders after cryomilling:

- Additive Manufacturing/3D printing

- Advanced thermal spray coatings

- Making enhanced parts via Spark Plasma Sintering

High Strength SPS Graphite Tooling

High Strength SPS Graphite Tooling Tungsten Carbide Tooling

Tungsten Carbide Tooling Carbon Graphite Foil / Paper

Carbon Graphite Foil / Paper Carbon Felt and Yarn

Carbon Felt and Yarn Spark Plasma Sintering Systems

Spark Plasma Sintering Systems SPS/FAST Modeling Software

SPS/FAST Modeling Software