Cryogenic Milling

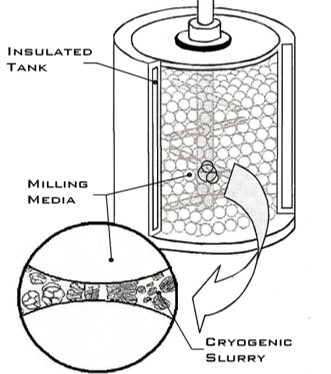

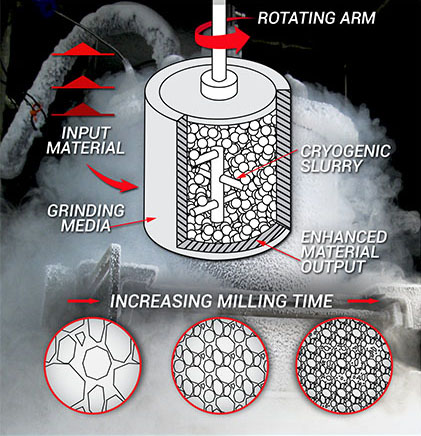

Cryogenic Milling has been proven to be one of the best techniques to produce large quantities of nanostructured/nanocrystalline materials which greatly improves the mechanical properties compared to their conventional counterparts. CalNano’s facilities include multiple cryomilling systems designed to safely process materials such as elemental metals, metal matrix composites, intermetallic compounds and more.

Cal Nano Cryomilling Toll Services:

- Collaborative R&D and pilot-scale production services are available

- High-quality customer service & quick turnaround times

- Customers can provide powder or it can be sourced by Cal Nano

- Batch sizes ranging from 500 grams to 7 kg

- Improving material strength through grain refinement in metallics

- Creating custom metallic alloys & refractory alloys

- Particle size reduction for ceramics, metals and polymers with the ability to reduce to sub-micron in certain materials

- Homogeneously mixing materials faster and more effective than traditional methods

- During cryomilling the material is fully submerged in liquid nitrogen or liquid argon, making it ideal for moisture sensitive or materials prone to smearing.

- Inert atmosphere suited for processing hazardous materials containing volatile components.

CRYOMILL BATCH SIZES

R&D – 500 grams and 1 kilogram

Pilot-Scale – ~7 kilograms

TYPICAL MATERIALS

Metallics – Magnesium, Aluminum, Titanium, Iron, Nickel, and their alloys

MMC’s – Metal with Al2O3, B4C, YSZ, and more

Battery materials - Nd, FeN, etc.

Refractory materials - Tungsten, Niobium, Zirconium, Hafnium, Tantalum, and more

Polymers (particle size reduction)

Some applications for powders after cryomilling:

- Additive Manufacturing/3D printing

- Advanced thermal spray coatings

- Making enhanced parts via Spark Plasma Sintering

Spark Plasma Sintering Systems

Spark Plasma Sintering Systems

SPS Starter Accessory Kits

SPS Starter Accessory Kits

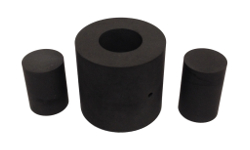

High Strength SPS Graphite Tooling

High Strength SPS Graphite Tooling

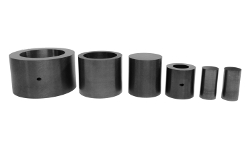

Tungsten Carbide Tooling

Tungsten Carbide Tooling

SPS Graphite Crucibles

SPS Graphite Crucibles

Carbon Graphite Foil / Paper

Carbon Graphite Foil / Paper

Carbon Felt and Yarn

Carbon Felt and Yarn

Quartz Glass Windows

Quartz Glass Windows

SPS/FAST Modeling Software

SPS/FAST Modeling Software