Planetary Ball Milling

Planetary milling is a grinding technique used to process materials by utilizing a planetary ball mill. This milling method involves placing the material to be processed along with grinding balls into rotating jars. The jars not only rotate on their own axis but also orbit around a central axis, resulting in a unique grinding motion. The collision of the grinding balls with the material leads to size reduction through mechanical impact and attrition. Planetary milling is known for its efficient and controlled grinding process, making it widely used in industries such as pharmaceuticals, ceramics, and materials science for applications like particle size reduction and homogenization.

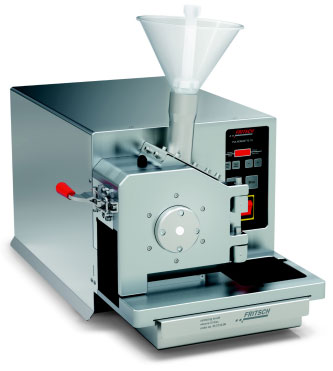

Pulverizing, on the other hand, is a process of reducing materials to fine particles or powder by various means such as mechanical grinding or crushing. This technique is utilized to prepare materials for further processing, analysis, or as a final product. Mechanical pulverizing involves using mechanical forces like grinding or crushing to break down the material into smaller particles. Impact pulverizing utilizes high-speed rotating hammers or impellers to impact and fracture the material.

High Strength SPS Graphite Tooling

High Strength SPS Graphite Tooling Tungsten Carbide Tooling

Tungsten Carbide Tooling Carbon Graphite Foil / Paper

Carbon Graphite Foil / Paper Carbon Felt and Yarn

Carbon Felt and Yarn Spark Plasma Sintering Systems

Spark Plasma Sintering Systems SPS/FAST Modeling Software

SPS/FAST Modeling Software