Material Development / Testing

Material development and testing are essential processes in the field of materials science and engineering. Let's explore each of these aspects in more detail:

1. Material Development:

Material development involves the creation and design of new materials or the improvement of existing materials to meet specific requirements. This process typically includes several stages:

a. Material Selection: Identifying the desired properties and characteristics required for a particular application and selecting the appropriate base materials or combinations of materials.

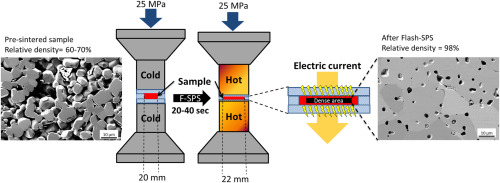

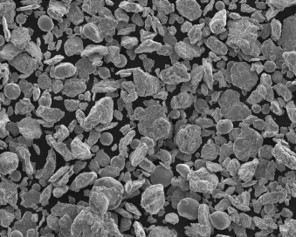

b. Synthesis or Manufacturing: Creating the material through various techniques such as casting, alloying, sintering, polymerization, or deposition methods like chemical vapor deposition or physical vapor deposition.

c. Processing and Treatment: Applying specific processes like heat treatment, surface modification, or mechanical processing to enhance the properties or tailor the microstructure of the material.

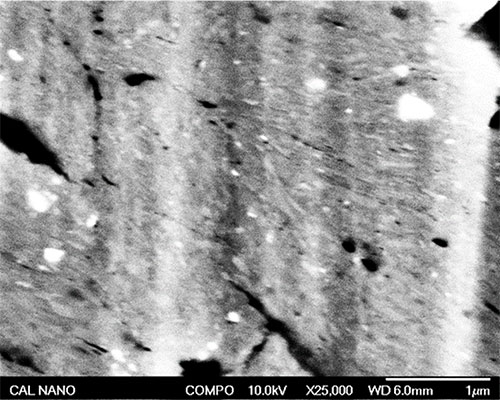

d. Characterization: Analyzing and evaluating the material's physical, chemical, mechanical, and thermal properties using techniques such as microscopy, spectroscopy, thermal analysis, mechanical testing, and more.

e. Optimization: Iteratively refining the material's composition, processing conditions, and treatments to achieve the desired performance, durability, and other required attributes.

2. Material Testing:

Material testing involves assessing the properties and behavior of materials under various conditions to ensure they meet specific standards, regulations, or application requirements. Testing can include:

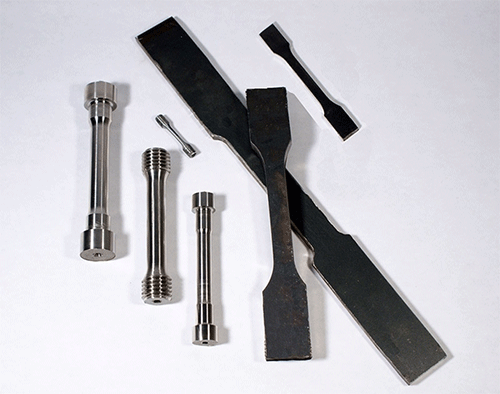

a. Mechanical Testing: Determining the material's strength, hardness, toughness, elasticity, fatigue resistance, and other mechanical properties using techniques like tensile testing, compression testing, impact testing, or hardness testing.

b. Thermal Testing: Evaluating the material's response to temperature changes, such as measuring thermal expansion, thermal conductivity, specific heat capacity, or assessing its behavior under extreme temperatures.

c. Chemical Testing: Analyzing the material's chemical composition, corrosion resistance, reactivity, or compatibility with other substances.

d. Microstructural Analysis: Examining the material's internal structure and morphology using microscopy techniques like optical microscopy, electron microscopy, or X-ray diffraction to understand the microstructure and its influence on properties.

e. Performance Testing: Assessing the material's performance under specific conditions or environments, such as fatigue testing, creep testing, wear testing, or environmental testing (e.g., exposure to moisture, chemicals, UV radiation, etc.).

Material testing ensures that the developed materials meet quality standards, regulatory requirements, and are suitable for their intended applications. It provides valuable data for further optimization and validation of material properties.

Both material development and testing are iterative processes, where insights gained from testing guide the refinement of material compositions, processing methods, and treatments to achieve the desired performance characteristics. These processes are crucial for advancing technology, improving material performance, and enabling the development of new and innovative materials for various industries.

High Strength SPS Graphite Tooling

High Strength SPS Graphite Tooling Tungsten Carbide Tooling

Tungsten Carbide Tooling Carbon Graphite Foil / Paper

Carbon Graphite Foil / Paper Carbon Felt and Yarn

Carbon Felt and Yarn Spark Plasma Sintering Systems

Spark Plasma Sintering Systems SPS/FAST Modeling Software

SPS/FAST Modeling Software