Mechanical Testing

Cal Nano's offers mechanical testing services that play a crucial role in complementing material development efforts by providing valuable insights into the mechanical properties of materials. Services include:

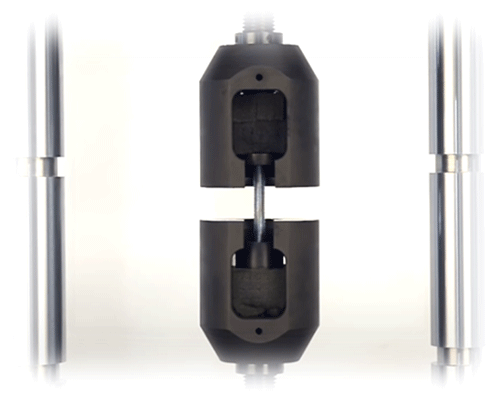

Tensile testing measures a material's strength, elasticity, and ductility, aiding in material selection and design optimization.

Compression testing evaluates a material's resistance to crushing or buckling,

Shear testing assesses its response to shear forces, essential for applications involving cutting or machining.

TRS testing determines a material's ability to withstand bending or torsional forces.

Hardness testing, including micro hardness, evaluates a material's resistance to indentation or penetration, providing insights into strength and wear resistance.

Planetary ball milling enables the production of fine powders or specific particle size distributions, facilitating advancements in pharmaceuticals, ceramics, and materials research.

Lastly, laser diffraction particle size analysis enables the precise measurement of particles and their distribution between 0.01um and 3.8 mm

By offering these comprehensive testing types, Cal Nano empowers researchers and engineers to make informed decisions, improve material performance, and enhance development efforts.

Spark Plasma Sintering Systems

Spark Plasma Sintering Systems

SPS Starter Accessory Kits

SPS Starter Accessory Kits

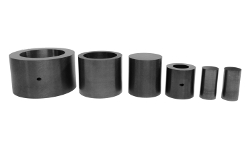

High Strength SPS Graphite Tooling

High Strength SPS Graphite Tooling

Tungsten Carbide Tooling

Tungsten Carbide Tooling

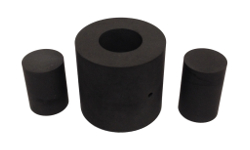

SPS Graphite Crucibles

SPS Graphite Crucibles

Carbon Graphite Foil / Paper

Carbon Graphite Foil / Paper

Carbon Felt and Yarn

Carbon Felt and Yarn

Quartz Glass Windows

Quartz Glass Windows

SPS/FAST Modeling Software

SPS/FAST Modeling Software